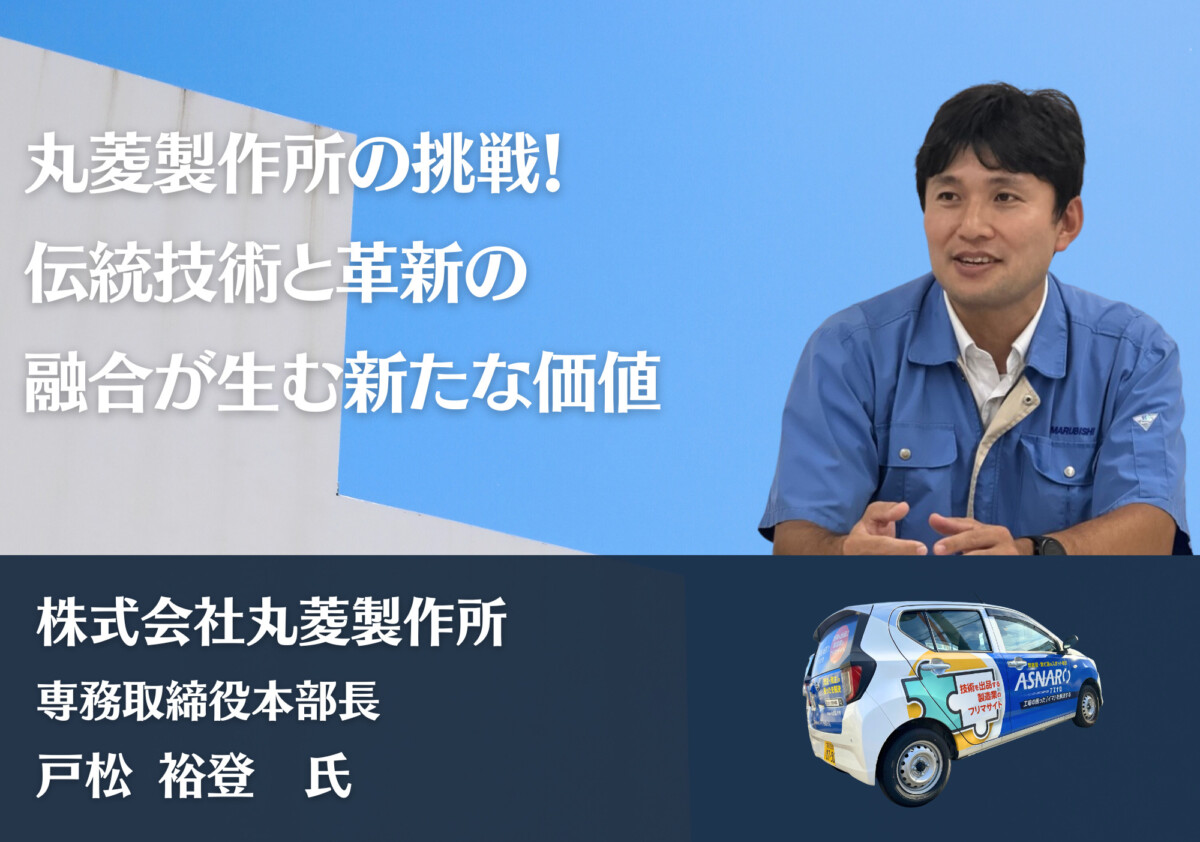

Marubishi Manufacturing’s challenge! New value created by the fusion of traditional technology and innovation | Marubishi Manufacturing Co., Ltd.

“Many may have heard the saying, ‘Japan’s manufacturing is supported by small and medium-sized enterprises.’ Japan is home to approximately 220,000 factory businesses that manufacture a variety of products with advanced technical skills. However, the manufacturing industry is facing a significant challenge with succession issues, leading to the closure of businesses that lack successors. In our interview, we spoke with Hiroto Tomatsu, Executive Vice President of Marubishi Manufacturing Co., Ltd., who is facing these manufacturing challenges head-on. Please feel the passion in Mr. Tomatsu’s message.

About the business of Marubishi Manufacturing Co., Ltd.

Could you tell us about your company’s business first?

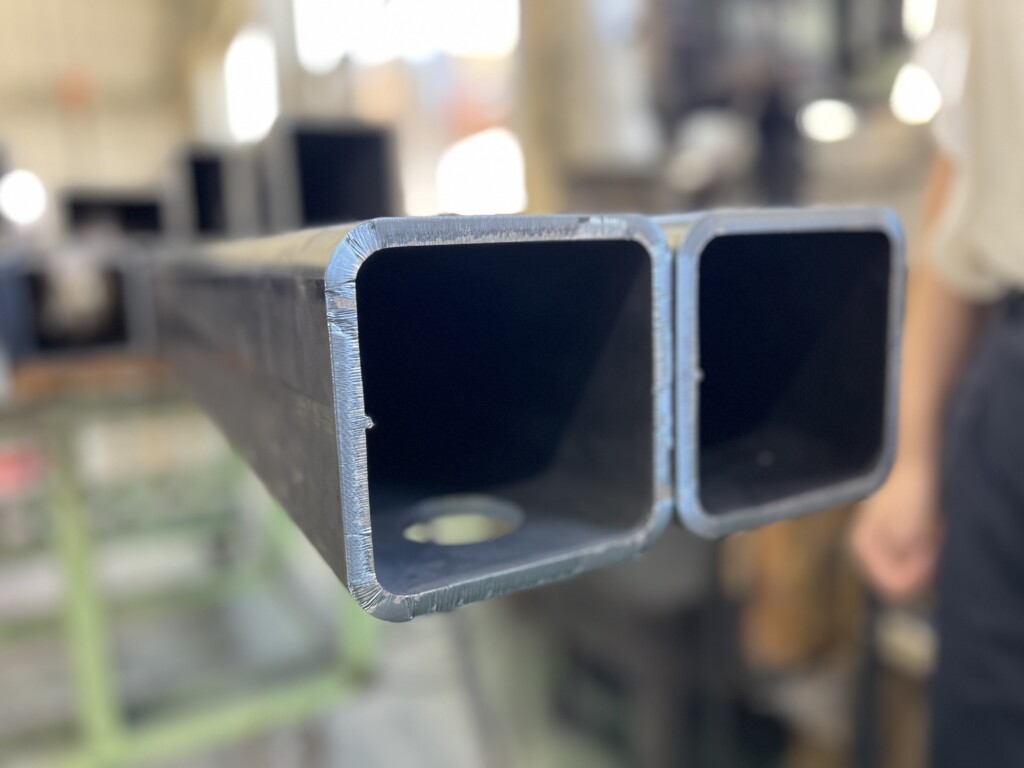

Marubishi Manufacturing Co., Ltd. has a history of 70 years since its foundation. As indicated by the character ‘菱’ in our company name, we started as a business to work for Mitsubishi Electric. Initially, we began with bolt rolling in Atsuta, a different area than the current Kasugai city. When the Ise Bay Typhoon struck in 1959, we moved our base to Kasugai city and started to meet customer demands by expanding into sheet metal, welding, and machine processing, not just bolts. Eventually, we began manufacturing large custom-made products, such as can manufacturing.

Now, we manufacture various parts, including the frames for elevators and large parts for machine tools. Our strength lies in utilizing the technology accumulated in-house to perform integrated production. Although we no longer roll bolts and our initial business has significantly changed, Marubishi Manufacturing’s commitment remains to create products that meet our customers’ needs to the fullest.

So you’ve grown your current business by closely listening to your customers’ needs!

By the way, does Mitsubishi Electric still account for a large portion of your sales?

Sales to Mitsubishi Electric account for about 90%. However, in this era of significant change, it would be fatal not to be able to adapt to the changes in the world. With this in mind, we are aiming for ‘qualitative growth’ and are challenging ourselves with new businesses.

It’s great to hear that you’re actively engaging in new businesses.

Can you tell us specifically which new businesses you are involved in?

In addition to our main business of manufacturing large custom-made can products, we are also involved in ‘Marine Business’ and ‘ASNARO Business.’ For the Marine Business, we manufacture awnings for ships, sold under the product name ‘Toma Awning,’ which was started by my father, the president of the company.

As a primary supplier, being part of the supply chain alone can lead to a fixed scope of work and difficulties in controlling sales prices. To break away from this, we started the Marine Business.

Indeed, being a primary supplier could make one vulnerable to price competition and price negotiation pressures.

I think there are three ways to set product prices. The first is ‘price calculated from manufacturing cost.’ The second is ‘price set through competition with other companies.’ Many manufacturers sell their products at prices determined by one of these two methods.

The third way to set prices is ‘based on whether the customer wants the product or not.’ Our Marine Business adopts this pricing method. To make this possible, we have developed and manufactured our own product, Toma Awning.

Developing and expanding your own product line with a different pricing strategy is indeed a brilliant idea!

It was a business that could be launched because of such flexible thinking.

The catalyst for starting the new ‘ASNARO’ project

Could you tell us what inspired you to start ‘ASNARO’?

‘ASNARO’ is a business I initiated. Just like our large can manufacturing business, working only within the supply chain inevitably leads to high dependency. In our case, 90% of our sales are currently from Mitsubishi Electric, but being dependent on them means we could lose to competitors with future changes. And even with 90% sales, it doesn’t necessarily mean our factory is operating at 90% capacity all the time. There are times during busy periods when we operate at about 200%, and times when we might be at only 50% capacity.

This situation leads to wasted production capacity, despite having the technology to consistently produce large cans. I believe it’s very risky to be able to sell only to existing customers. ASNARO was created as a marketplace to freely sell the technology that small factories like ours possess.

Moreover, what a supplier we deal with said was quite shocking to me. They mentioned, ‘If this equipment breaks down, I’m thinking of quitting this business.’ These words weren’t uttered during a reduction in work due to COVID-19; they came at a time when work was expected to increase.

That’s a shocking statement…

Why would they say such a thing when more work is expected?

They explained it this way: ‘Until now, if we invested in equipment, we could always expect to recoup the costs within a few years. There was no uncertainty. But the work in Japan now is unpredictable even five years ahead. If we continue working the same way as before, it might take 30 years to recoup the investment. We don’t have the surplus or future prospects to survive until then, so while we’ll continue our current work with the equipment we have, we can’t just aim for the next 30 years based on the current state.’

This statement really paints a picture of the current situation faced by small factories.

Is ASNARO a service started to address these kinds of issues?

These concerns are not unique to that supplier; our company is no exception, and I believe there are many other companies with similar worries. However, until now, there was no service available to solve these problems. That’s why we created ASNARO.

Could you give us more details about what the ASNARO project involves?

There are many companies in Japan with wonderful technology. However, there are doubts about whether that technology is being fully utilized. There are cases where people cannot request services because they do not even know such companies exist. By listing their technology on the ASNARO platform, it becomes more widely known, creating new job opportunities.

During slow periods, companies can list their technology as products on ASNARO, and during busy periods, they can utilize the technology of other companies. This is what can be achieved by using the ASNARO platform.

It sounds like a service that many have been seeking but didn’t exist until now!!

This must be in demand by many.

Regarding the future PR strategy for ‘ASNARO’

Can you tell us about the future PR strategy for ASNARO?

At present, we believe it’s important to firmly establish ourselves within the small network in Aichi Prefecture. Facebook initially became popular within Harvard University, then spread to a network of famous universities before expanding further. Similarly, we feel it would be difficult for ASNARO to spread in areas with no connection or relevance, so rather than aiming for a nationwide rollout immediately, we want to steadily expand within Aichi Prefecture, the center of manufacturing.

Starting locally is a very good approach!

What specific activities are you undertaking?

We’re engaging in traditional sales methods, starting with phone appointments, followed by visits to explain about ASNARO. Currently, only those who resonate with our vision for ASNARO are registering.

So, you are starting with telemarketing. It’s admirable that you are registering people who truly share your passion!

This circle of empathy seems like it could lead to something really exciting.

Indeed. However, a platform like this can solve problems using a common mechanism throughout Japan. If we have ‘ASNARO in Aichi and another platform in Gifu,’ it will become difficult to solve the fundamental issues.

Certainly, creating different platforms for each prefecture would prevent cross-prefectural collaboration.

That’s why the nationwide expansion of ASNARO is such an important mission!

We definitely want to expand nationwide! One approach could be for Marubishi Manufacturing to set up branches in each prefecture. However, there is a genuine concern about whether we can gain empathy outside of Aichi Prefecture.

Therefore, we are looking to gradually change our framework to include partners who share ASNARO’s vision in various regions, to help us expand together.

We hope to realize a situation where trusted partners nationwide are spreading ASNARO as soon as possible! Are there any other initiatives you are undertaking to make ASNARO known?

We are participating in business pitch contests. Until now, we have focused on Aichi Prefecture, but in April 2023, we won the Minister of Economy, Trade and Industry Award at the Japan Junior Chamber Inc.’s Value Design Contest. We are gradually taking steps to become known nationwide. We hope to gather partners who will recognize us and help spread ASNARO further.

Winning the Minister of Economy, Trade and Industry Award at the Value Design Contest seems to significantly contribute to ASNARO’s awareness.

What is your timeline for national expansion?

With the aging of the baby boomer generation, it is said that by 2025, there will be a nationwide shortage of about 5 million workers, with the manufacturing industry facing a shortage of about 600,000 workers. In such a situation, a service like ASNARO will become absolutely necessary. We believe it is crucial to have a solid structure in place by that time. We aim to achieve nationwide deployment by 2027, to be of service to everyone across the country.

So, 2025 is the immediate hurdle.

When spreading ASNARO to everyone, are there any specific points you are focusing on?

We focus on conveying our ‘passion’ and gaining ’empathy.’ ASNARO is a place where those seeking the wonderful technology held by small factories can find it. However, to facilitate such transactions, the number of companies registered with ASNARO is crucial.

We are making phone appointments to increase this number, but about 30% do not answer the phone. And as soon as we mention ‘matching,’ another 30% hang up. For the rest, when we explain with passion that ‘we want to achieve what matching alone cannot,’ about 70% end up registering. If we lack ‘passion’ during these phone appointments, even fewer would register.

Currently, we are in the stage of gathering companions who ’empathize’ with the philosophy of ASNARO. However, by 2025, we must also talk about ‘benefits.’ We want to prepare thoroughly so that we can confidently say that registering with ASNARO will definitely yield profits.

We strongly hope that by 2025, ASNARO’s platform will have fostered many good connections!

There are many small factories with wonderful technology in the world.

We will make such companies the main players on the ASNARO platform!!

The Sentiment and Future Vision for the Business

Could you share with us your sentiments regarding the business?

I am set to become the third-generation representative of Marubishi Manufacturing, and I approach this role with the intention of continuing the story built by my predecessors. Within this context, I think about what I personally can contribute.

I want to honor what Marubishi Manufacturing has done so far and fulfill the dreams of the previous generations. There are companies that conduct their business with processes fully automated 24/7. In such companies, you might find that out of 100 employees, 98 are involved in programming, and only 2 are actually on-site—a surprising staffing structure.

However, that’s not how Marubishi Manufacturing operates. If we did, it would negate everything we’ve built up until now. In our company, 70 out of 100 employees are involved in manufacturing. My goal is to create a place where the work of these 70 employees is properly valued.

Having a management team that thinks this way gives employees a reason to strive, doesn’t it?

Originally, I wasn’t someone involved in manufacturing, but now I’m completely fascinated by the technology behind it. If someone like me can become so immersed, I believe there must be something inherently interesting about manufacturing.

That’s why at Marubishi Manufacturing, we don’t just do the same thing every day; we’re always eager to take on new challenges and ensure that everyone finds manufacturing interesting!

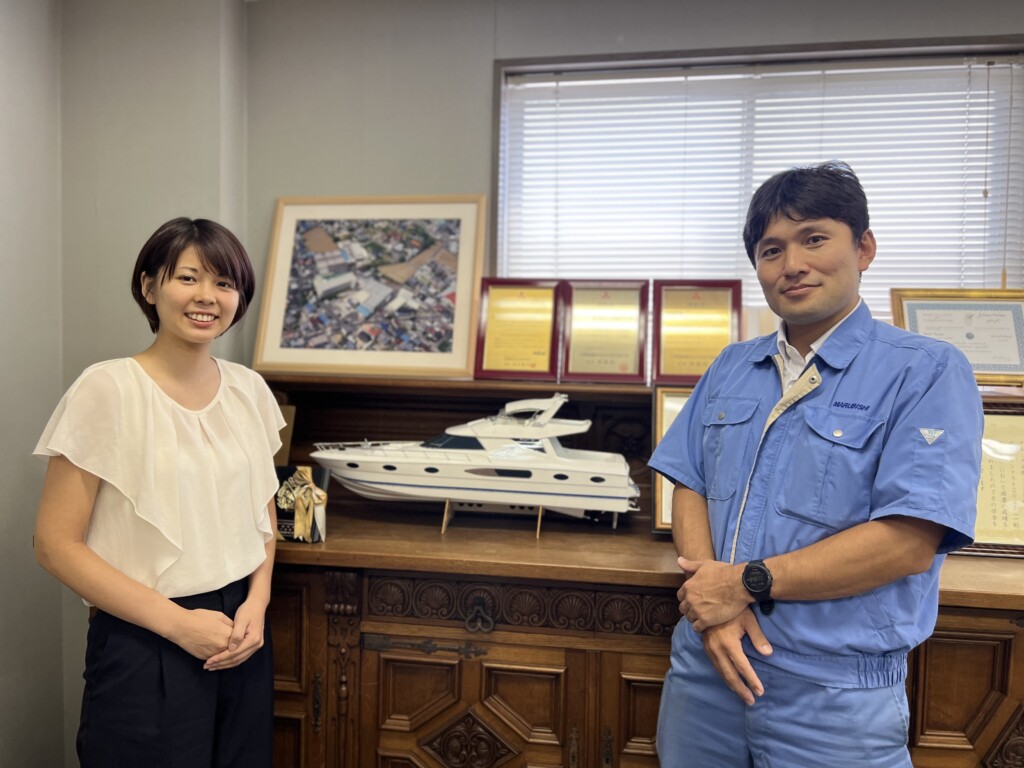

A Word from the Editorial Department

In this interview, we had the pleasure of speaking with Hiroto Tomatsu, Executive Vice President of Marubishi Manufacturing Co., Ltd., based in Kasugai City, Aichi Prefecture. The story of transitioning from no involvement in manufacturing to being captivated by its fascination represents the allure of “monozukuri” (the Japanese concept of craftsmanship). Throughout the interview, Mr. Tomatsu spoke passionately. His energy was palpable, and I am confident that he will significantly advance the company’s mainstay in large can manufacturing and new ventures like ASNARO.

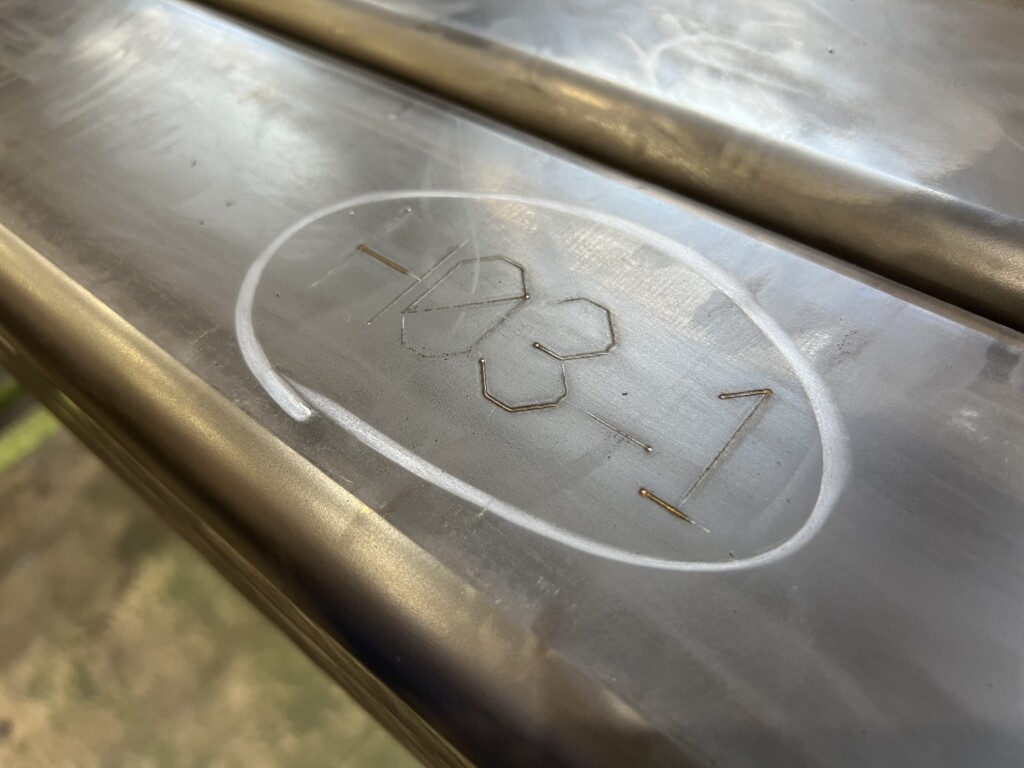

gallery

Hiroto Tomatsu Profile

1986年に愛知県で生まれ、早稲田大学を卒業後に家業である株式会社丸菱製作所に入社。現在は、株式会社丸菱製作所 専務取締役本部長という立場で丸菱製作所の経営に関わる。本業の製造とは異なるウェブプラットフォーム事業である「ASNARO」の立ち上げなど、過去の常識に捉われない行動力を持つ。

趣味は、ロードレース。特技のカラオケ(モノマネ)はお客様から好評。座右の銘は「目の前の課題に取り組んだ結果が将来を作る」「ワークアズライフ」。

Company Profile of Marubishi Manufacturing Co., Ltd.

| Founding | April 1, 1952 |

| capital | 36 million yen |

| location | 1045 Kawauchi, Otemachi, Kasugai City, Aichi Prefecture |

| number of employees | 102 people |

| Business content | Elevator, escalator heavy structure parts, 3D laser processing Thick sheet metal can processing, large-scale machining, painting, assembly Manufacture and sales of Toma Awning, an awning for pleasure boats. Operation of manufacturing processing ordering platform ASNARO |

| URL | Marubishi Manufacturing Website Toma Awning Website ASNARO website |

御社の想いも、

このように語りませんか?

経営に対する熱い想いがある

この事業で成し遂げたいことがある

自分の経営哲学を言葉にしたい

そんな経営者の方を、コントリは探しています。

インタビュー・記事制作・公開、すべて無料。

条件は「熱い想い」があることだけです。

経営者インタビューに応募する

御社の「想い」を聞かせてください。

- インタビュー・記事制作・公開すべて無料

- 3営業日以内に審査結果をご連絡

- 売上規模・業種・知名度は不問

※無理な営業は一切いたしません

発信を自社で続けられる

仕組みを作りたい方へ

発信を「外注」から「内製化」へ